Top Material For

Top Sealing Performance

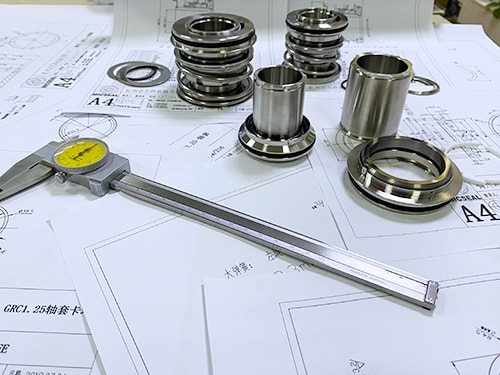

MINKIX understands how important the material is for realizing the ideal sealing performance. We continuously seek qualified suppliers of quality materials at fairs in all parts of the world, aiming to bring you mechanical seals that work perfectly.

Over the years, we have accumulated in-depth knowledge about selecting the right material, which secured business success for thousands of our clients. Learn the material portfolio now.